Quality Management

Realize customer satisfaction all over the world through strict quality control.

The first step of K-mush’s commitment to provide the best mushrooms to customers starts with thorough and rigorous quality control.

We strictly manage the entire process from cultivation such as safety inspection of raw materials, storage room management, packaging and transportation environment management to delivery to customer’s dining table and strive to maintain customer confidence.

-

1. Operation of Co-brand and Production History ID

Monitor the production history of mushrooms for export and investigate the corresponding farm in case of quality problems.

view

1. Operation of Co-brand and Production History ID

Monitor the production history of mushrooms for export and investigate the corresponding farm in case of quality problems.

view

-

2. Production of Quality Control Manual

Establish detailed quality control guidelines and regularly train export farms to produce high quality mushrooms.

view

2. Production of Quality Control Manual

Establish detailed quality control guidelines and regularly train export farms to produce high quality mushrooms.

view

-

3. Operation of Quality Control Enterprise Organization

Compose quality control advisory committee including mushrooms cultivation management specialists, storage and distribution specialists and the representatives of exporters.

view

3. Operation of Quality Control Enterprise Organization

Compose quality control advisory committee including mushrooms cultivation management specialists, storage and distribution specialists and the representatives of exporters.

view

-

4. Introduction of Quality Control ERP System

Collect and manage real-time environmental information by stage after harvesting to maintain quality

view

4. Introduction of Quality Control ERP System

Collect and manage real-time environmental information by stage after harvesting to maintain quality

view

-

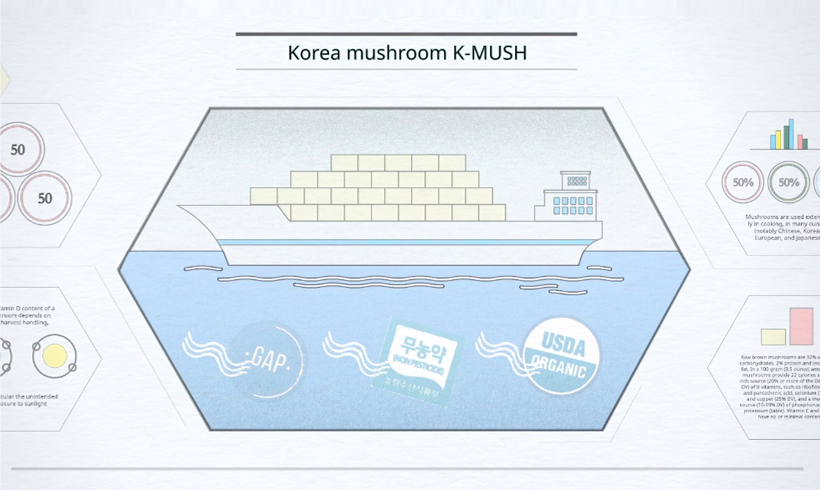

5. Safety Certification System

Hold domestic and foreign certification proving the high quality and high safety of mushroom

view

5. Safety Certification System

Hold domestic and foreign certification proving the high quality and high safety of mushroom

view

-

6. Residual Pesticide Inspection System

Ensure safety through the Positive List System

view

6. Residual Pesticide Inspection System

Ensure safety through the Positive List System

view

-

Operation of Co-brand and Production History ID What is Production History ID?

Operation of Co-brand and Production History ID What is Production History ID?"Production history ID refers to the numbering system that K-mush controls by providing each number to all export farms, and contains major historical data such as region, item and producer.

K-mush’s Commitment

The production hisgtory ID is obligatorily attached to all packaging boxes exported under the K-mush’s brand and is transparently disclosed to consumers to guarantee the quality of K-mush’s products. "We are strictly managing the farms to prevent the same problems from occurring by investigating the occurrence of claims and by constructing and managing production traceability system that meets the value and status of Korean mushrooms of K-mush. We will also actively contribute to healthy food culture of the world by strengthening our quality competitiveness and improving the reliability of overseas customers.

-

Production of Quality Control Manual What is Quality Control Manual?

Production of Quality Control Manual What is Quality Control Manual?The quality control manual is a guideline for the management of internal and external factors affecting hygiene and quality throughout the entire process, from mushroom growth to shipment before export. K-mush provides standard points for all export farms to produce high quality products with these guidelines. This means that only high quality products are produced under the K-MUSH’s brand, and it has steadily gained the confidence of customers around the world.

K-mush’s Commitment"We are striving to increase the production of high quality mushrooms through educating farms by producing and distributing quality control manuals for each mushroom item, and managing compliance with manuals by visiting member farms regularly.

In addition, we are striving to export only the best mushrooms that meet the quality standard by preparing, operating and managing the export quality standards for each country and grade, which are accompanied by real photos to check the suitability of high quality grades such as shape, size and color. " -

Operation of Quality Control Enterprise Organization What is Quality Control Enterprise Organization?

Operation of Quality Control Enterprise Organization What is Quality Control Enterprise Organization?"K-mush operates a separate quality control committee and contributes to improving the competitiveness in exports and external awareness through strengthening the quality control of exported mushrooms.

K-mush’s Commitment

The quality control committee is composed of mushrooms cultivation management specialists, storage and distribution management specialists, the representatives of exporters and so on and regularly discusses related issues. ""In addition to regular meetings, the quality control committee will solve the quality-related issues through frequent discussions whenever important issues arise.

We will listen to the voices of consumers as well as farms and strive to become the world’s leading export mushroom brand with high consumer confidence." -

Introduction of Quality Control ERP System What is Quality Control ERP?

Introduction of Quality Control ERP System What is Quality Control ERP?We utilize the quality data of individual farms as the basic data for integrated management and quality improvement through ERP system that integrates various databases related to quality control into one system using the latest IT technology. In addition, we operate double-management system to maintain ideal levels by collecting temperature and humidity data of key locations of all farms such as storing and packaging room and reporting them to K-mush and individual farm when they exceed the proper range.

K-mush’s Commitment"We are operating the integrated management of factors that directly related to quality in entire process before export by introducing cutting-edge quality control system. In addition, we are continuing to make investments in improvement of export environment and production of high quality mushrooms using the collected data.

Through our quality control system, we will lead the highest customer satisfaction by keeping pace with rapid change in market environment and diversified demands." -

Safety Certification System K-mush’s Certificate Management

Safety Certification System K-mush’s Certificate ManagementIn addition to Global GAP, which is an internationally recognized standard for good agricultural products, Korea strictly manage good agricultural products by preparing GAP and Environment-Friendly Certificate System. Environment-Friendly Certificate is a certificate system at the stage of cultivation including the use of pesticides and chemical fertilizers, and GAP is a certificate system for the prevention of harmful substances in the distribution process from the farm to the table of customers around the world.

K-mush’s Commitment"K-mush’s farms have a variety of certificates that demonstrate the safety of exported mushrooms such as Global GAP, GAP and Environment-Friendly Certificate.

We are striving to produce safe mushrooms that our customers can trust by managing certificates recognized domestically and internationally, and we will do our best to help export farms concentrate on producing better quality mushrooms by maintaining their certificates. " -

Residual Pesticide Inspection System What is Positive List System?

Residual Pesticide Inspection System What is Positive List System?Positive List System, a national system that prohibits the use of pesticides with no domestic registration or maximum residue limit (MRL) criteria, is designed to prevent the production of mushrooms that have not been proven to be safe in advance and manage to export safe mushrooms.

K-mush’s Commitment"Export farms should keep and record pesticide application records and submit them to the inspection agency when inspecting residual pesticides. Also, they should inspect pesticide ingredients that are used in cultivation process or have high detection frequency.

K-mush ensures the safety of exported mushrooms by obliging residual pesticide inspection and pesticide application record and guiding to get support for the part of inspection fees."